Finite Elements Method Analysis

Finite Elements Analysis (FEA, Finite Elementisis) is a powerful engineering tool that innovated the way projects are designed, evaluated and optimized. With the ability to virtually simulate the behavior of complex structures, mechanical components and systems, finite element analysis has become a key piece for companies that seek efficiency in their projects.

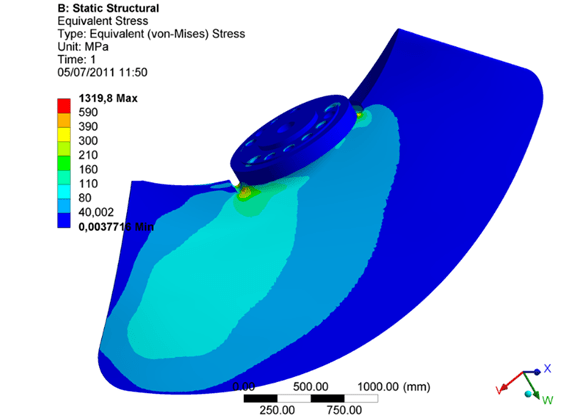

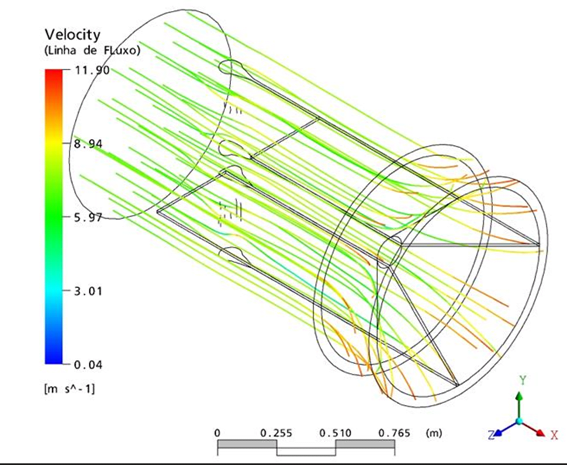

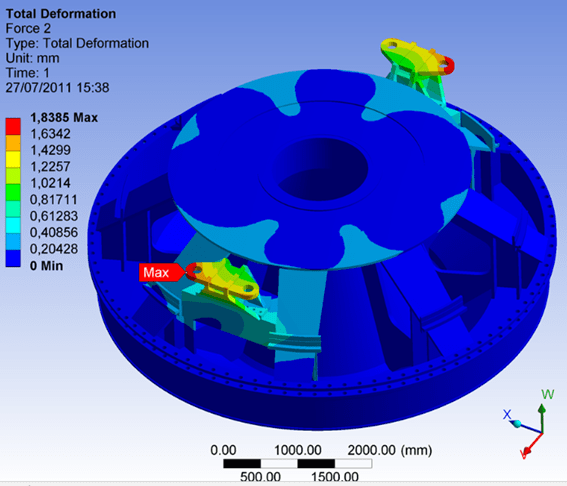

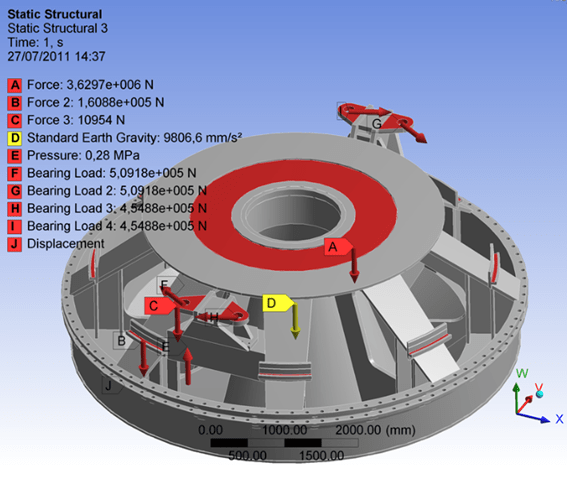

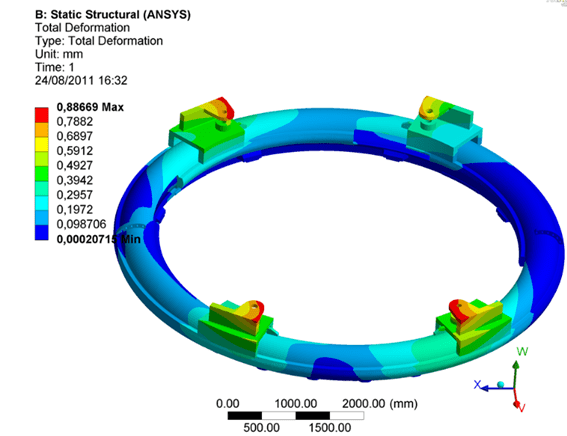

Through advanced mathematical techniques to divide a structure or component into smaller elements, which can be easily analyzed individually. Each element is represented by mathematical models that describe their physical behavior, taking into account factors such as load, tension, deformation and contour conditions. Through the resultant in tensions, charges and deformation calculated mathematically, and on time it is possible to obtain accurate information about the performance of the structure or component under different conditions.

One of the main advantages of finite element analysis is its ability to provide a detailed view of structural behavior. By simulating the project virtually, one can identify excessive tension points, unwanted deformations and risk areas. Assisting construction to optimize it and analyze critical points even before the assembly and operation of the structure, and may avoid unwanted costs, and unnecessary overdimensions. In addition, finite element analysis also allows us to explore different scenarios, such as load variations, materials and geometry, to obtain a robust and effective project.

One of the main advantages of finite element analysis is its ability to provide a detailed view of structural behavior. By simulating the project virtually, one can identify excessive tension points, unwanted deformations and risk areas. Assisting construction to optimize it and analyze critical points even before the assembly and operation of the structure, and may avoid unwanted costs, and unnecessary overdimensions. In addition, finite element analysis also allows us to explore different scenarios, such as load variations, materials and geometry, to obtain a robust and effective project.

With current modeling software, it is created a great facility to model and analyze structures as complex as they are and with a greater number of details that in turn has full importance within Fea, because the quality of the mesh also optimized and much taken into consideration, thus making the analysis and optimization process even more efficient.

However, it is important to emphasize that finite element analysis requires specialized technical knowledge to ensure accurate and resistant results. The correct interpretation of the results is the great key to success in building the project. It is also worth mentioning that experimental proof is paramount for a complete and functional analysis.

SNEF Brasil has an engineering prepared to meet the demands of our customers, with experience and expertise acquired in over 35 years of services and projects related to power generation that total over 2 GW, distributed among hydroelectric plants, small centrals Hydroelectric, thermoelectric, photovoltaic parks and substations.